Posted by Lindsey Carroll on 1st Apr 2015

How to Choose a Kiln

How to Choose a Kiln

You will need to know the following things before choosing the right kiln.

Will you be primarily using your kiln to fire ceramic or glass?

What capacity will you need?

Consider the following:

What are the dimensions of the largest piece you will want to fire?

What is the maximum volume of work you will want to fire at one time?

How will your needs grow in the next 5 years?

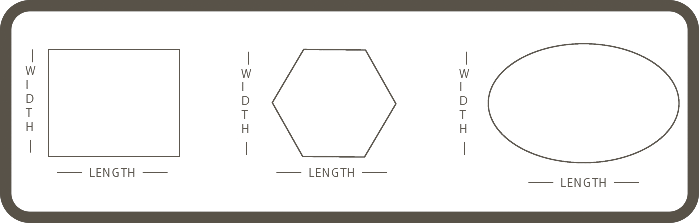

The following images represent interior kiln shapes. Use them when considering your chamber capacity needs.

Skutt kilns vary in the following dimensions: (minimum to maximum)

Width: 11” to 46”

Length: 11” to 31”

Depth: 9” to 36”

Determine your available power supply: Voltage, Amperage and Phase.

Each kiln model is offered in options designed to operate on the varying electrical services available today. It is important to know the electrical service of your building. Ordering a kiln for a different service can be very frustrating and expensive to correct. Contact an electrician to verify voltage, amperage, and phase of the electrical service at the location where the kiln will be installed. Keep in mind, to use your kiln, most people will need to have an electrician install the circuit breaker and wall receptacle as well as the wire that runs from the receptacle back to the circuit breaker panel.

Voltage (208 or 240) – A common misconceptions regarding voltage is that “220” is an actual voltage reading in the USA, which is inaccurate. Rather, “220” is a generic term used for household appliances that can run on either 208 Volt or 240 Volt systems. As a general rule 208V and 240V supplies are common in schools and businesses and 240V is common in residential areas. Exceptions are quite common so check with an electrician to be sure.

Amperage– Most buildings have limited amperage available without having the power company upgrade service. In most cases it will be necessary to install a dedicated circuit breaker to run the kiln. Your circuit box or fuse panel must have room for the breaker or fuse that corresponds to the model kiln you choose. In general, larger kilns draw more amperage and require a larger circuit breaker.

Phase (1-phase or 3-phase)– Kilns can be wired for 1-phase or 3-phase power supplies. 1-phase (or single-phase) power supplies have 2 current carrying wires and a ground wire and are common in residential and industrial areas. 3-phase (or three-phase) power supplies utilize 3 current-carrying wires and a ground wire and are usually only found in businesses and institutions. There are exceptions, and some buildings have both supplies available.

To what temperature do you need your kiln to fire?

Kilns are designed to fire to a variety of temperature ranges. We find that customers gravitate to one of the four common temperature ranges: glass (1600 degrees F), low-fire ceramic (cone 06-04 or 2185 degrees F), mid-fire ceramic (cone 4-6 or 2250 degrees F) or high-fire ceramic (cone 9-10 or 2350 degrees F). Whenever possible you should choose a kiln that exceeds your temperature needs. Higher temperature kilns are designed to withstand more wear and tear on a kiln. Thus your kiln will endure more firings when frequently firing below what it is designed to withstand.